Introduction

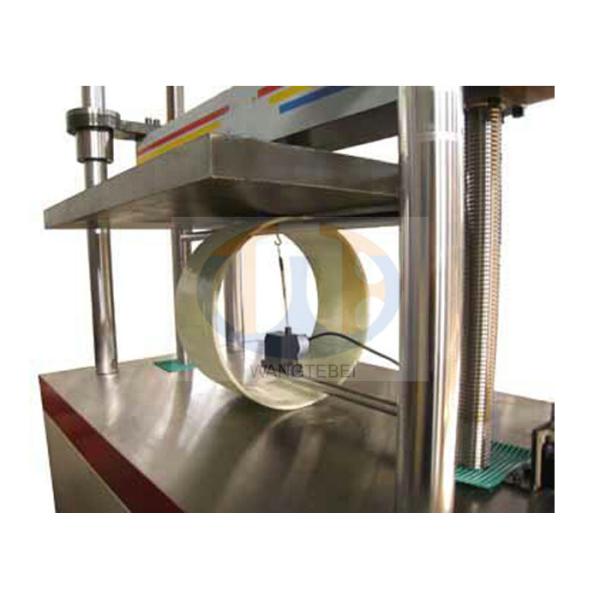

1) The machine has large test space, applicable to pipes less than

3000mm, mainly used to measure ring stiffness, ring flexibility,

flattening, deflection properties.

2) With precise automatic control and data acquisition system to

realize full digitalization adjustment to data acquisition and

control process.

Test Standards

→GB/T9647 Thermoplastics pipes-Determination of ring stiffness

→GB/T18042 Thermoplastic plastic tubing creep ratio test method

→GB/T14452 Bending mechanical properties test method

→GB/T18477.1 Unplasticized polyvinyl chloride (PVC-U) structure

wall pipline system for underground soil waste and drainage-Part1:

double wall corrugated pipes;

→GB/T18477.2 Underground drainage with rigid polyvinyl chloride

(PVC -u) structure wall pipe system Part 2: reinforced pipes

→GB/T18477.3 Underground drainage with rigid polyvinyl chloride

(PVC -u) structure wall pipe system Part 3: axial hollow double

wall pipe

→GB/T21238 Glass fiber reinforced plastics mortar pipes;

→CJ/T270 Steel reinforced spirally wound Polyethylene(PE) drainage

pipe;

→JT/T529 Plastic bellows for prestressed concrete bridge;

→JG225 Corrugated metal ducts for prestressed concrete;

→GB/T18742.1 Hot and cold water piping system with polypropylene:

general rules-Part 1

→GB/T2918 Plastic sample status to adjust and test standard

environment

→GB/T8806 Plastic tubing size measurement method

→GB/T19472.1 Buried wall pipe with polyethylene (PE) structure

system Part 1: polyethylene double-wall corrugated pipe

Polyethylene structure wall pipeline system for underground usage

Part1:Polyethylene double wall corrugated pipes;

→GB/T19472.2 Buried wall pipe with polyethylene (PE) structure

system Part 2: polyethylene winding structure wall pipes

Polyethylene structure wall pipeline system for underground usage

Part1:Polyethylene double wall corrugated pipes;

→EN 13476-1 Pressureless buried sewage drainage with thermoplastic

plastic pipe system rigid polyvinyl chloride (PVC -u),

polypropylene (PP) and polyethylene (PE) of the structure wall pipe

system in the first part: pipes, pipe fittings and pipeline system

specification, "about the requirements of part B polyethylene

structure wall tube

→ISO 9969 The determination of thermoplastic pipe ring stiffness

Technical Specification

WDW-20R/30R/50R/100R Computer Control Ring stiffness Testing

Machine(CE); |

1 | Max. load | 20kN/30kN/50kN/100kN |

2 | Load class | Class 0.5 / class 1 |

3 | Measuring range of load | 0.4%~100%FS/1%~100%FS |

4 | relative error of indicating value | ≤±0.5%/ ≤±1.0% |

5 | Load resolution | 1/±300000F.S |

6 | measuring range of deformation | 0.2%~100%FS |

7 | Displacement speed | 0.01~500mm/min |

8 | displacement accuracy | within ±0.2% of the set value |

9 | Test space | 0~3000mm |

10 | measuring range of deformation of inner diameter | 10~3000mm |

17 | measuring range of pipes | Diameter DN10~DN3000mm |

18 | span between columns | 680mm or customized as required |

19 | Compression platen (L*W) | 620x310mm or customized as required |

20 | power voltage | 220V±10% 50Hz |

21 | motor power | 2.0kW |

22 | Dimension of loading frame (L*W*H) | 1100x700x3500mm |

Order Policy

1. MOQ: 1 set

2. various payment terms

Price Policy

1. Product prices: fixed price in 1 year for agents.

2. Freight charges: according to actual cost payment, refund for

any overpayment in next order.

Delivery Policy

1. Try to catch up with contract delivery time.

2. If can’t, try to catch up with the arriving date.

3. Chang shipping by sea to delivery by air flight if necessary.

Before Service

1. Offer actual details for your consideration (such as what we can

do and what we can’t do).

2. Quality standard: ASTM, BS, EN, DIN, ISO and others.

After Service

1. Technical education and training (in factory’s house, agent’s

house, or through internet).

2. Quality assurance time: 1 year.

Special Service

1. ODM service

2. OEM service

3. Collection service, to collect items from other factories which

you buy and delivery in container.